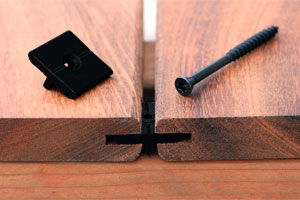

If you are installing quality hardwood, soft wood, composite or synthetic decking of any kind you now have a choice between face screws and our Ultimate Concealed Deck Clip System. Our system combines incredible holding power with incredible ease of installation. It's a Concealed Deck Clip System that requires no pre-drilling. Constructed from Marine Grade Aluminum, uses a strong T20 Star Drive Black Oxide stainless steel screw which holds the decking much tighter than plastic clips and allows for the inevitable movement all deck materials experience. As a bonus our unique fastener installs in about the same time as pre-drilling and face screwing! Should a board need replacing - no problem! Our system allows you to get to the screw from the top. Not the bottom or at an angle as some competitive systems do.

If you are installing quality hardwood, soft wood, composite or synthetic decking of any kind you now have a choice between face screws and our Ultimate Concealed Deck Clip System. Our system combines incredible holding power with incredible ease of installation. It's a Concealed Deck Clip System that requires no pre-drilling. Constructed from Marine Grade Aluminum, uses a strong T20 Star Drive Black Oxide stainless steel screw which holds the decking much tighter than plastic clips and allows for the inevitable movement all deck materials experience. As a bonus our unique fastener installs in about the same time as pre-drilling and face screwing! Should a board need replacing - no problem! Our system allows you to get to the screw from the top. Not the bottom or at an angle as some competitive systems do.

- Marine Grade Aluminum

- The Concealed Deck Clip System that require no pre-drilling and no messy adhesives

- Star Drive Stainless Steel screws included

- Holds the decking much tighter than plastic clips

- Allows for the inevitable movement all decks experience

- Works with all types of hardwood, most composites, PVC and softwood decking

The Ultimate Concealed Deck Clip System Packaging

Each unit contains:

- (175) Clips

- (175) 2-1/4" Star Drive Stainless Steel screws,

- (10) 2-1/4" Star Drive Stainless Steel starter and finisher screws

- Hardwood Hole Plugs

- (1) T20 driver

- Instructions.

Each unit will install 100 square feet of 5.5" wide decking on 16” centers, or 150 square feet on 24” centers.

Aluminum, ACQ and Corrosion

The Ultimate Concealed Deck Clip System is manufactured out of the same grade of aluminum used on marine applications worldwide. 6063T5. The Clip is suspended above the substructure to keep the board tight but still allow the deck boards to expand and contract. There is no contact to the pressure treated wood below.

-->